BB86/BB92 Bottom Brackets with a 30mm or SRAM DUB Crankset – A recipe for disaster

30mm cranks into BB86 bike frames – Avoid if you can…

A common question I am often emailed about is asking if I can supply a bottom bracket that will allow a 30mm crank to be fitted into a BB86 bike frame. This post will talk through the many problems associated with this.

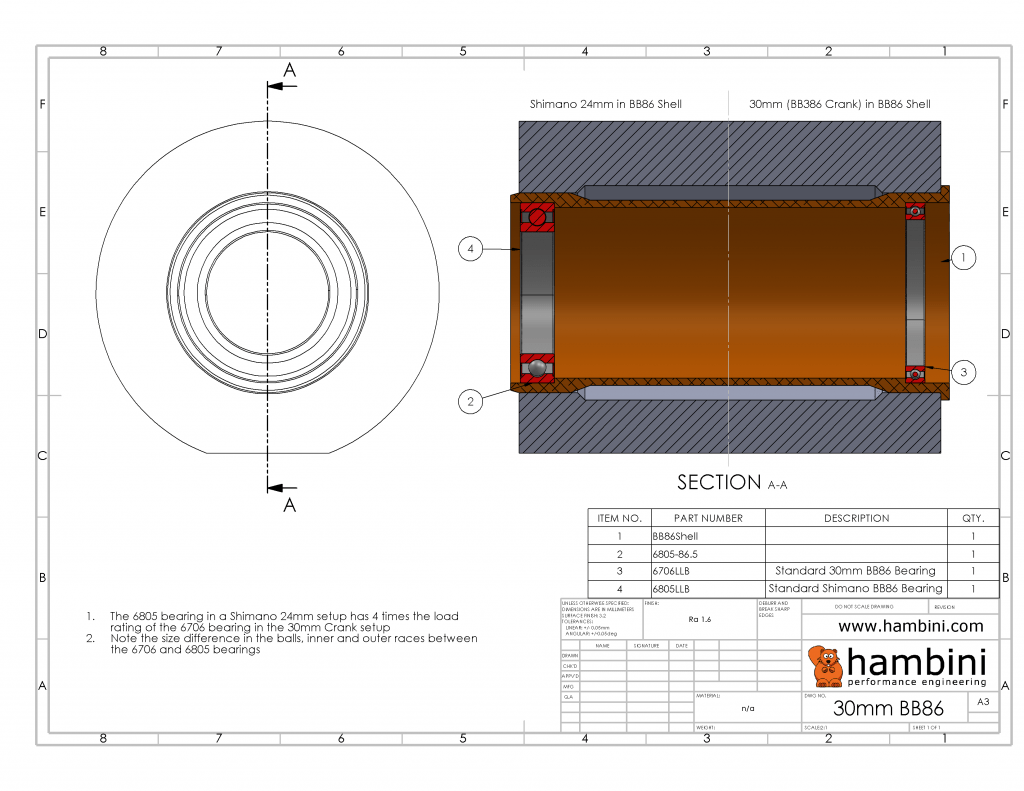

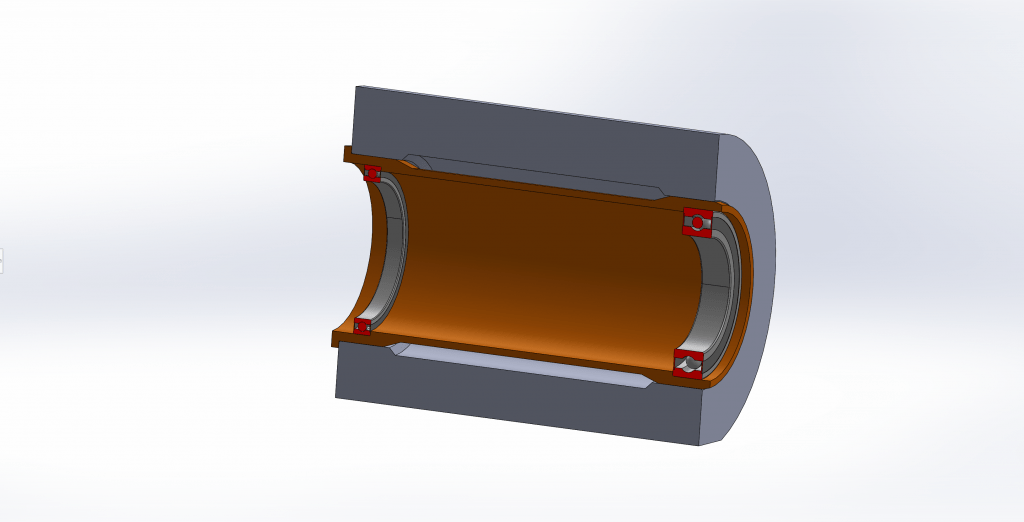

BB86 uses a bottom bracket with a diameter of 41mm and a width of 86.5mm (Drawing shown below). In practice these are nominal dimensions and have a tolerance on them that makes them slightly smaller. BB86 is a Shimano standard and is used by lots of frame manufacturers (BMC, Canyon, Look etc). BB86 is effectively the pressfit version of an ISO threaded bottom bracket.

The size of Shimano and it’s market share allows them to dictate standards and as such to an external engineer looking in, it appears that Shimano designed BB86 to try and exclude (or make it very difficult) to run a 30mm crank. Shimano uses a 24mm crank as standard which is a combination of 6805N bearings and nylon inserts to make up the difference in the bore.

A lot of people have 30mm / DUB cranks and a large number of those individuals have power meters attached to them and understandably don’t want to purchase a new power meter, they would rather find a solution to allow fitting in a BB86 shell. As a result a number of companies have produced bottom bracket solutions. I use this term loosely because there are some severe performance limitations that they omit from their product pages.

There are two popular methods of BB86 30mm / DUB bottom bracket design. I will cover them both

From left to right. A 6805, 6706 and 6806 bearing. Note how slender the 6706 bearing is in comparison to the others

Method 1 – Modified 6806 bearing

The original BB30 specification and 30mm cranks as a whole, are designed to run inside 6806 bearings. Irrespective of BB30, PF30, BBright or BB386EVO etc – there may be a cup between the bearing and the frame but all of these standards use 6806 as a design basis. Unfortunately this bearing is fractionally too large to fit into a BB86 shell. A BB86 shell is 41mm and a 6806 bearing is 42mm on the outside diameter. Hence a rather crude solution is to machine or grind 1mm from the outer race of the bearing.

This might sound like an easy and perfect solution but it has some implications for performance. Grinding down the outside of a 6806 bearing by 1mm reduces the strength of the outer race and it is much more likely to deform. Any rider that is putting a large amount of torque through the cranks – typically going up hill, will be deforming the bearing outer race significantly.

At a torque of 50Nm (~500W at 100RPM) the deformation is over 9 times worse than an unmodified 6806 bearing.

Correspondingly the bearing life is also reduced.

Method 2 – Use 6706 bearings or a Double row bearing

6706 bearings have an outside diameter of 37mm so they will comfortably fit inside a BB86 bottom bracket shell. They are however quite difficult to obtain and of the tier 1 manufacturers, only SKF have them readily available. Several bottom bracket suppliers use these bearings inside machined cups.

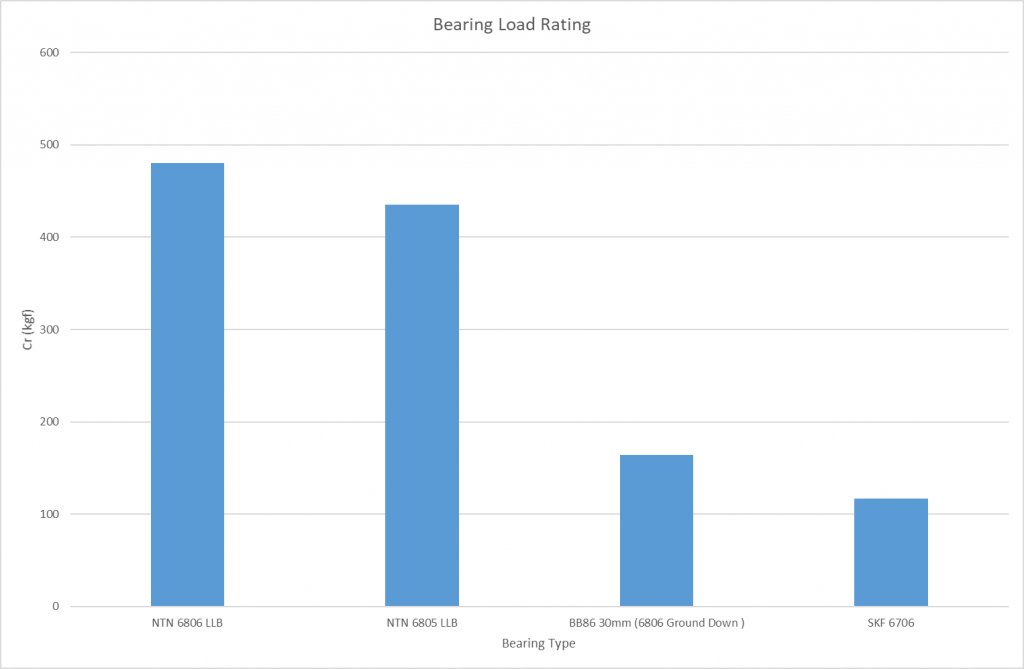

These bearings have an EXTREMELY low load rating, it is about 25% of the load of a 6806 bearing which is the next size up (used in BB30). Realistically, a rider would expect to achieve only 25% of the life or could only put through 25% of the peak torque before the bearing would fail.

A minor modification to this method is by using a double row ball bearing. This increases the life marginally but it is still far short of either a 6805 or 6806 bearing.

Performance

In every criteria of performance, running a 30mm crank in a BB86 shell is suboptimal. Friction, bearing life, stiffness and load rating are all significantly worse than running a 24mm crank or using a bike frame with a larger diameter bottom bracket

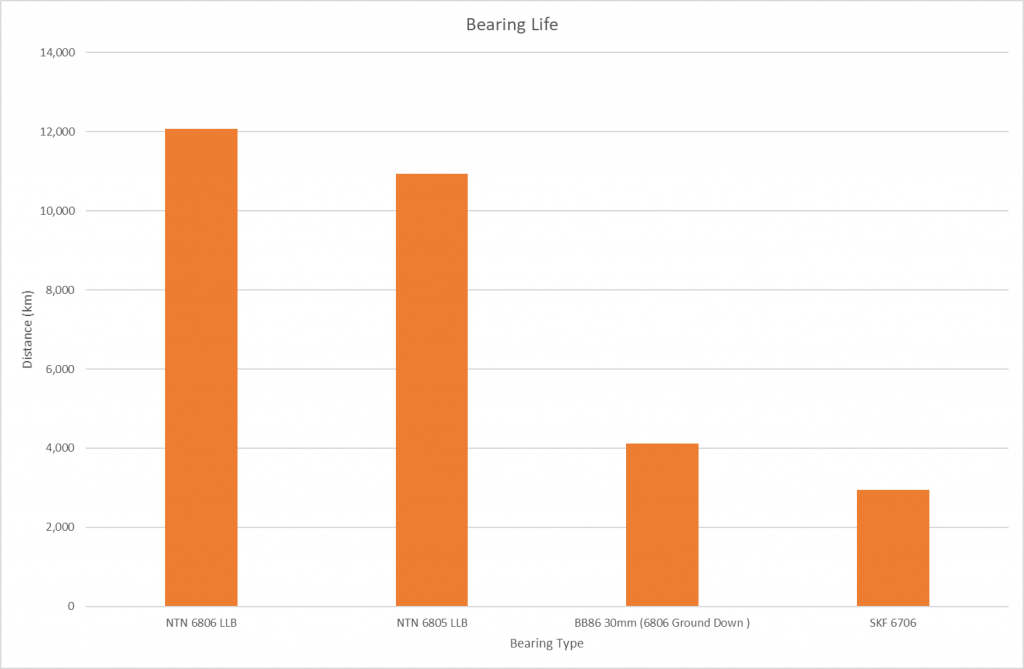

The graph below shows the relative friction against distance travelled for each type of bearing. Having had a discussion with SKF technical support, their conclusion was the 6706 and ground down 6806 were in an overloaded state due to the sinusoidal loading. Their firm recommendation was to avoid using these bearings in this application.

The Life chart speaks for itself

Load rating can be obtained from bearing handbooks. They are an effective way of predicting bearing life using an L10 calculation. The slender 6706 and ground down 6806 bearings have a substantially reduced load capacity in comparison to the 6805 and 6806 bearings.

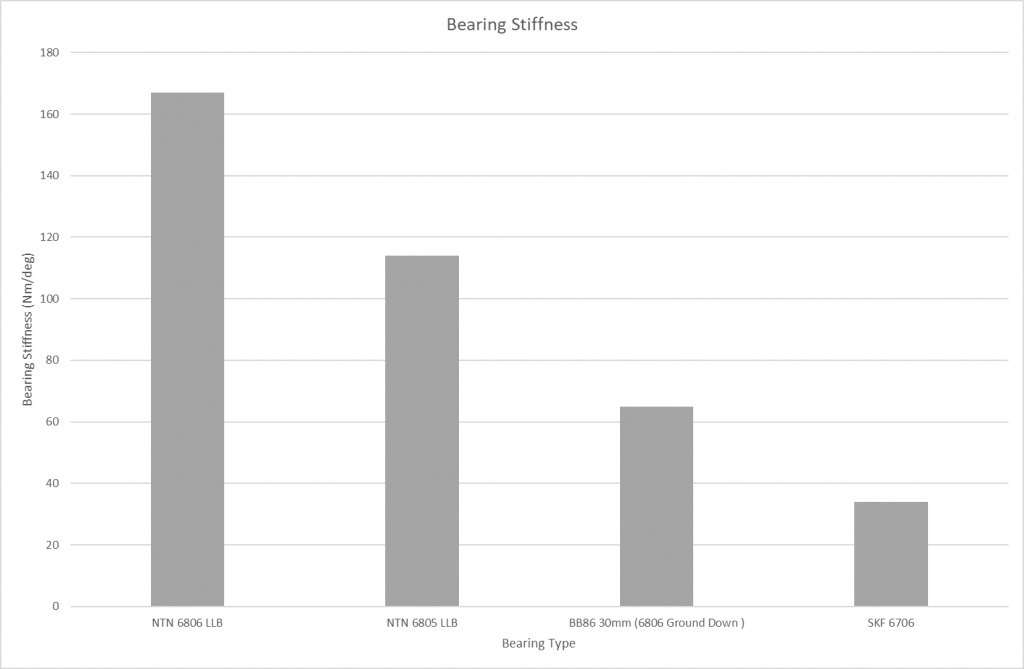

An often overlooked parameter is bearing stiffness. When using 6806 and 6805 bearings, this is not usually a problem because the bearings are robust and stiffness can be ignored until very large torque is encountered at which point they flex and deform. In a 30mm to BB86 application this deformation limit occurs much earlier and even a modest rider will be able to feel spongeyness at power levels of ~250W.

Conclusion

Using a 30mm crankset in a BB86 should be avoided. The likelihood of a failure is very high. I receive countless emails every week about people having problems with their 30mm cranksets in BB86 bike frames. My usual recommendation is to try a different crankset with a smaller diameter axle.

There will inevitably be anomalies in any data analysis and plenty of people will be able to use their 30mm crankset without having seen any problems however the engineering analysis clearly demonstrates this practice should be avoided.

Have you looked at the bbinfinite bb86 DUB bottom bracket? They have a proprietary bearing they claim to provide a viable solution. Would like to hear your take.

It looks like a cheap far Eastern bearing to me

Ended up trying it. $200 bb in order to save me from buying a $600 pm setup. Been 3 months of riding with no issue. Hopefully they will last. Will update after a hard summers worth of riding. For reference I ride 13-20hrs a week and race whenever I can so they will have a significant amount of load cycles by next fall.

Sean — Please post an update, I am somewhat persuaded by the BBInfinite sales pitch. I have a BBI in a current bike and am very happy with it, but am replacing the bike with a BB86 bike and want to take my PF30 Quarq power meter with me.

No issues with the bb over the last 6 months. Lots of race days and training on it (mostly in dry weather, road another bike on rainy days) Concerned about when I will need to service the bearings as it looks like it will be difficult to extract the bearings with the internal sleeve in the way.

Hi Sean, requesting another update 6 months further along, if possible?

Would you buy this again?

I’ll thinking about a 30mm crank in my BB86 and BB92 frame bikes, road and mtb respectively.

Kurt

No mention on the 4130 BB Rotor and Ceramic Speed put out? At $40 for the Rotor, they seem to work just fine.

Does it really work? Any low load rating issue?

On the Rotor 4130 front I have gone through several in the last 18 months – both types, one even lasted 3 weeks. I had a Hope version as well and that failed (failed as in the bearings rusting up). At the Monet I’m using the Race Face Cinch version on both of my bikes and its a hit and miss at the meant…

Hi Sean, im also considering the BBI route, are you able to share your experience so far?

Thank you for this really helpful article, I’m about to order a Sram Red 12 speed chainset for my Bianchi Specialissima which is BB86 and was deliberating in the DUB chainset or the GXP version, I’m going GXP after reading this. Many thanks.

Are you happy with your decision? I would be interested in Hambini’s opinion on this, since he does not like GXP as well 🙂

I have a Scott Addict RC with BB86 and want to upgrade the stock Force DUB crankset to Red, but also can choose between DUB or GXP (with GXP having 50g weight penalty).

Another super helpful post. Love your channel and the unorthodox approach to marketing “truth”

Just out of curiosity, I have a (probably) very stupid question on the 6806. Is there a side where grinding is preferrable? Would grinding the internal side or both sides equally (0.5mm) would have a significant impact here?

you want to avoid grinding anything if you can. It’s better to grind off two sides if you have to and you would really need to be desperate to have to.

What do you even mean by “side”? The bearing is ground down because it’s outside diameter is 1mm too large for the BB shell.

What about some kind of bastardized cup and cone style bearing system? Would there just be too much torque for that?

It’s too small to get an angular contact bearing of any decent size in there. Shimano made it small to make it difficult for anyone else to do something,

I’m having this exact dilemma with my PF86 bike at the moment, whether to go GXP or DUB axle. SRAM tech support said DUB is 28.99mm and the 1mm difference from a BB30 is sufficient to get a reasonable sized bearing in there. What are your thoughts?

Hello,

Any thoughts or review on Wheels Manufacturing product “Flanged, Dual Row Pressfit 86/92 ABEC-3 Bottom Bracket (BB86 To 30mm)” ?

you’ve always got the problem of low load rating.

Ok thanks. I guess I should have been more carefull with compatibilities before bying this BB30 crankset…

Is it possible/practical to convert a Sram DUB 30mm (28.99mm) bearing/crank set up to a 24mm system and would I get increased bearing life in doing so – I wouldn’t mind getting a whole new crank set/bearing/chain drive to do this – if it is worth it?

You could move to GXP to get you down to 24mm drive side and 22mm non drive side. It’s not the best system though.

Hi Hambini, I just checked the Canyon Ultimate CF SLX 9 Disc eTap bike specs, and they do exactly this: SRAM Pressfit RED DUB (28,99mm axle) bottom bracket in a pressfit BB86 frame. What is your view on this? I’m building a new bike (PF BB86 frame) with a quarq PM and would rather not use GXP. Or should I?

On a BB86 frame, GXP is a better option than DUB. You will get better bearing life.

I just found out that I have this exact combination – BB86 with an Easton SL90 30mm Crankset.

What is the best bottom bracket to use in this case? Or should I rather replace both Bottom Bracket und Crankset?

Thanks a lot for help!

From a technical perspective, it’s better to go to a smaller crank axle. However, if you don’t put out a lot of torque, you may be okay with some 30mm BB’s if you are prepared to change the rolling elements frequently.

Hi, thank you for the article. Normally i don’t put a lot torque, so I guess I can keep the 4130mm BB option (also because of the budget)

It seems like the modified 6806 is a relatively better option in this case. Is there any brand offering this 6806 bearing ?

Thanks a lot.

I am 78kg and 1.8m tall, I am only a semi casual rider. FTP 235W. I tried the BBinfiinte and Rotor PF4130 bottom brackets. These bottom brackets are bearings that have a large portion of them ground down. Performance was okay initially for 250km but then they started to drag. At about 500km I heard a ping from the BBinfinite and it sounded like someone had put stones into a washing machine. I swapped it out for a Rotor, that lasted barely 1000km before the bearings sounded like gravel.

My experience with this setup has not been great. I wish I had found this webpage first.

Great article and timely for me, looking at a Ti frame that unfortunately has a BB86 shell. Wonder what you think of the Praxis approach to this for their M30 system – I like the look of the Zayante chainset and can’t tell whether their BB86 bearings are custom or ground down etc

There appears to be a new variant from Fushi bearing called MR3040H7-2RS that’s available in both steel and hybrid ceramic varieties . With ID=30/OD=40mm the dimensions are well matched to 29/30mm axles and appears to be designed specifically for BB applications. How does this bearing compare to the options referenced in this post? This looks like a favorable option for a 1-piece or joining 2-piece BB assembly where the bearings could be replaced easily, but only BB infinite makes such an assembly and their option is very expensive.

It has a very thin inner and outer race so it’s not particularly stiff. You’ve lost about 20% of the wall thickness in an effort to get it down to size. Additionally, Fushi aren’t exactly known for bearing technology.

Hambini – what’s the minimum permissible/acceptable dimension and variation of the BB86 shell hole? The shell on my new titanium frame varies between 41.00 and 40.60 according to my digital callipers. I can install a wheels mfg thread together BB without too much trouble but the (GXP) crank doesn’t spin as freely as I would expect. A bog standard plastic cup bb is a much tighter fit and the cranks barely spin at all. I’ll be talking to the shop and maybe the frame builder next week, would be good to have some technical information to hand when I talk to them. Cheers

On Ti it really needs to be between 40.98 and 41.00. If the frame has been welded, then it’s quite possible the shell has distorted during welding – this depends on whether they threaded before or after the event.

I think that’s what I have in my BMC Roadmachine with a SRAM Force axs (came like this from BMC). I have 15,000km on it and I have vibration when under load. Any solution so far?

Only to move to a 24mm or campag setup.

Hey Hambini nice to catch you here now I can’t on Weightweenies anymore haha.

I was pretty determined on putting a Quarq DFour on my Canyon Endurace CF SL 2019 until I became aware of this issue you highlighted.

Now I am very reluctant and considering going for a Power2Max instead and then running Rotor Aldhu cranks with Shimano chainrings. I’ve watched your Aldhu video of course, but I believe it’s still better than the Ultegra chainset I have on now. Then I am tempted to add in your BB86 once it becomes available.

Let me know what you think –

1. Quarq DFour is a no go on DUB BB86 (should be avoided at least)

2. Power2Max spider with Aldhu crankarms will perform at least similarly to my current Ultegra setup.

I can’t really comment on the power meter end of accuracy but aiming for a 24mm or 25mm axle would be preferred from a mechanical perspective.

Thanks, noted. Incredibly quick response too.

That’s what I was wondering and the Rotor has the 24mm axle.

Good article as always. I’ve unfortunately ended up in this situation, as the otherwise wonderful frame I’ve purchased has BB86 😖

I’ve decided to go down the “chuck-money-at-the-problem” road to find a solution, and settled on a Enduro XD15 4130 BB. What’s your thoughts on this solution? Additionally, I’m a little concerned about spinning axle, and internal hoses/wires. Are there any sleeves or similar available that can protect the axle?

not every frame is going to be able to have a protective sleeve, it will be on a case by case basis. I have not found a solution that works for this application.

Have you seen the new Enduro MaxHit BB’s? Apparently the cups themselves are the outer races which allows for larger bearings. Thoughts?

How is this solution working out so far Larsvagen? Are those Enduro double row XD-15 bearings holding up?

These look like a viable solution to me as well – thoughts and experiences would be a welcome addition to this discussion

Just adding to the experiences. BB86 with SRAM DUB and the Kogel BB with a 40/29/7 bearing lasted 450km. For as long as I have that combination, I will have to change bearings every 400km, it appears.

I have a 2022 Scott Foil RC PF BB86. I have the option to use a BB86 1-piece GXP and use SRAM Red D1 GXP cranks. Would this be more optimal over a PF BB86 DUB 2 piece with DUB Cranks?

Very interesting.

I ride a Time alpe d’huez with the BB386evo standard. Is it a durabilty or safety problem to ride an SRM crankarm with shimano ? They say it’s a 30mm spindle…

I have a Rotor crankset with a 30mm spindle, which I run on my Ridley with BB86. I had a bad experience with Rotor bearings, both Ceramic and steel. Perhaps I now know why! I have now installed Enduro bearings, their DRF 3041 LLB BO – Black Oxide, Flanged, Double-Row, Press-In, Bottom Bracket bearing – 30mm x 41/44mm x 11mm, which seem to be working very well. I’ve probably ridden about 4,000 km on them so far, without any issues, and they remain very smooth, as far as I can tell. I also put a fair amount of torque through them, as I do a fair bit of climbing and a lot of gravel and I weigh over 90 kg. I like the Rotor cranks, because I run them with direct mount machined chainrings, which I don’t think they do with a 24mm spindle. I’m about to get a BMC Teammachine as a replacement for one which was written off in a crash, so another BB86. I’m going with the Dura Ace groupset, so 24mm cranks and I am definitely going to be swapping out the bearings for a Hambini one piece BB.