Nepest Maui Road Bike Wheels: Unexpectedly Good

Full Test Results

Nepest have allowed the full test findings to be shared, you can download them here

Introduction

When I first came across the Maui wheelset from Nepest, my expectations weren’t high. It’s a brand I’d only seen in Instagram ads, and I assumed it might fall into the “generic and forgettable” category.

However, when the wheels arrived, I was immediately surprised. The packaging was typical of most wheelsets, but the real difference came when I opened the box. It was clear this was a polished product. The wheels were immaculately packed and came in their own wheel bags—strong, well-padded, and perfect for safely transporting the wheels in a car. These aren’t throwaway bags either; they’re the kind that many riders buy separately, yet here they were included as standard.

Alongside the wheels and bags were some spares and neatly organized paperwork, all presented with care. The attention to detail suggested a level of design oversight that felt aligned with Western markets—tidy, thoughtful, and intentional.

As for the wheels themselves, initial impressions were excellent. They were true out of the box, the bearings spun smoothly, and the end caps fit snugly. These qualities set the stage for the systematic testing I conducted later (more on that below).

Wheel Rims

The front wheel has an internal width of 20.6mm and an external width of 28.3mm. These dimensions place it within a moderate range by contemporary standards, suitable for a variety of tire profiles without being classified as excessively wide. The rim depth is 35mm, and the weight of the wheel is 558g. The rim features a hooked bead design and is tubeless-compatible; however, tubes were used for the purposes of this evaluation.

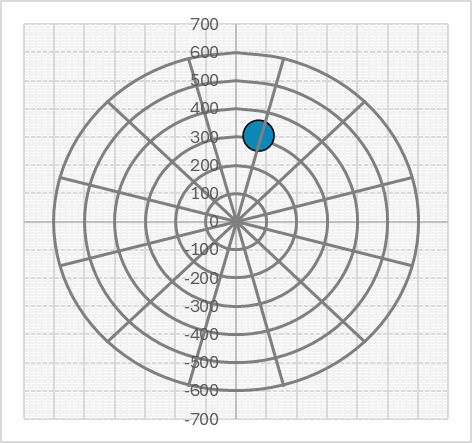

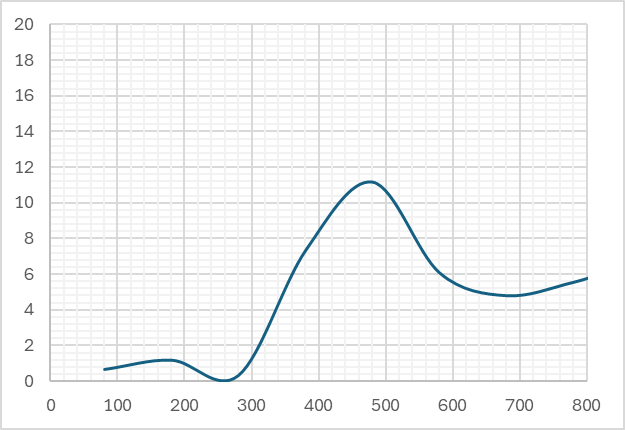

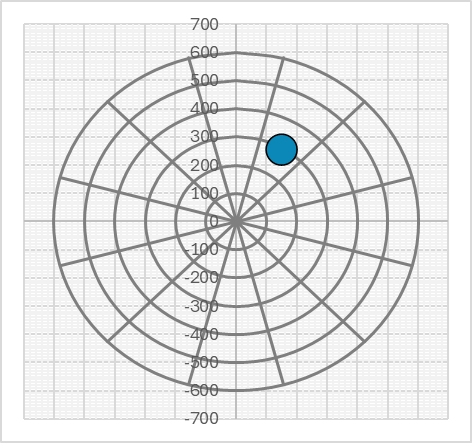

Balance testing indicated an out-of-balance measurement of 314g.mm at an angle of 14 degrees relative to the valve. The wheel exhibited low vibration up to approximately 350 RPM. Beyond this threshold, vibration levels increased progressively, with a critical vibration point observed around 450 RPM. This behaviour may influence performance under high rotational speeds and should be taken into account depending on the intended use case.

This assessment highlights the wheel’s design parameters and dynamic performance characteristics, providing a foundation for comparison with other wheels in similar categories.

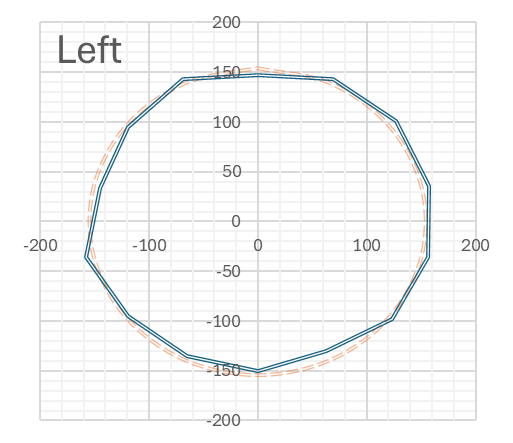

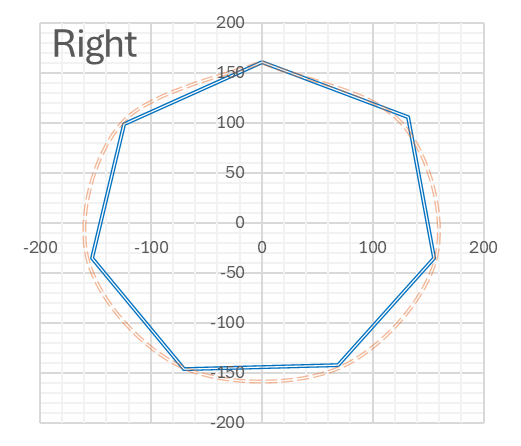

The spoke tension over the wheel was quite even.

The performance of the rear wheel was similar

Hubs

The hubs in this wheelset follow a design that has become standard in modern offerings. They utilise disc ratchets for power transfer, a mechanism originally patented by DT Swiss. With the expiration of this patent, many new hubs have adopted the pawless disc ratchet design. While opinions on the advantages of power delivery and noise reduction remain mixed, this design offers notable manufacturing benefits. It is both cost-effective and faster to produce, and its compact structure allows for smaller diameter bearings, contributing to reduced drag and weight.

The Nepest hub uses the same DT splined tool to facilitate removal fo the drive side rear wheel bearing.

The Nepest rear hub exemplifies this design philosophy. Although the identity of its OEM is unclear, the hub has performed faultlessly during use, suggesting a well-executed implementation of the disc ratchet system.

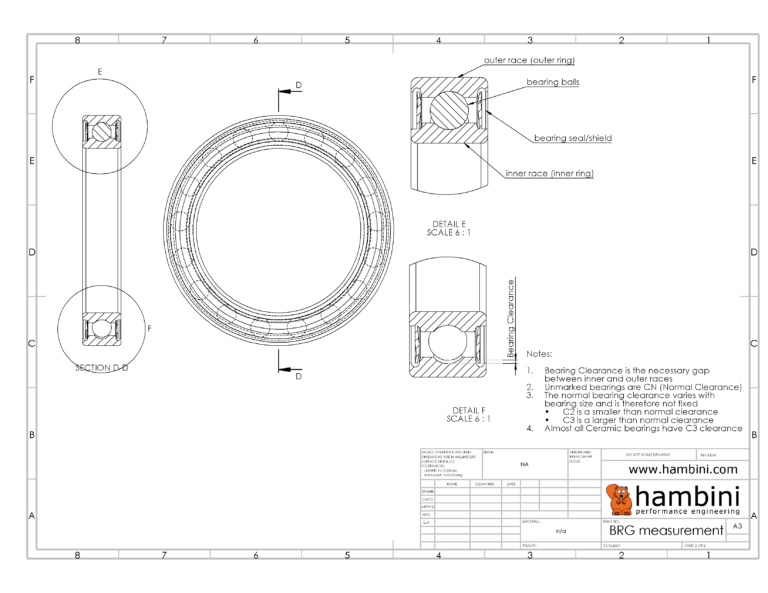

All bearings in the assembly are 15267, they are an OEM brand. Some of the fault frequencies on the front wheel were a little high initially but these soon tapered off, indicating the bearings were new and required some running in. The bearing fits on all locations were good.

Aerodynamic Performance

Aerodynamics has become a less dominant focus in recent years, driven by the recognition that the average speed of a club cyclist is approximately 28 km/h, significantly lower than the 50 km/h speeds typically used in aerodynamic testing. Furthermore, the transition from rim brakes to disc brakes has led to wider wheel designs, based on the premise that increased width improves aerodynamic performance.

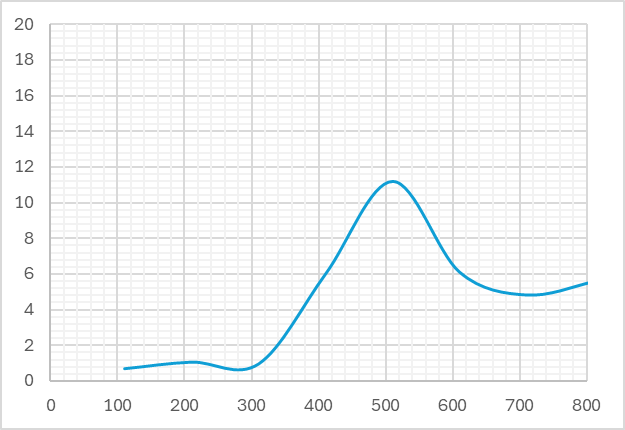

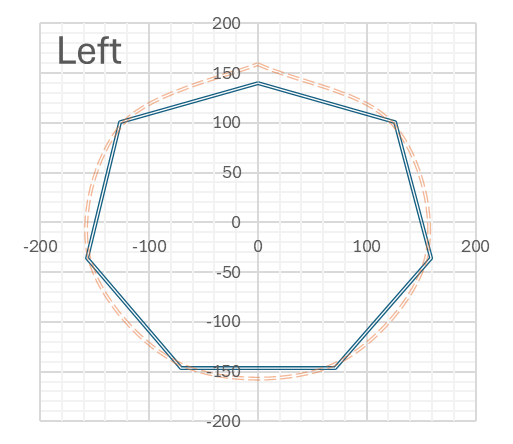

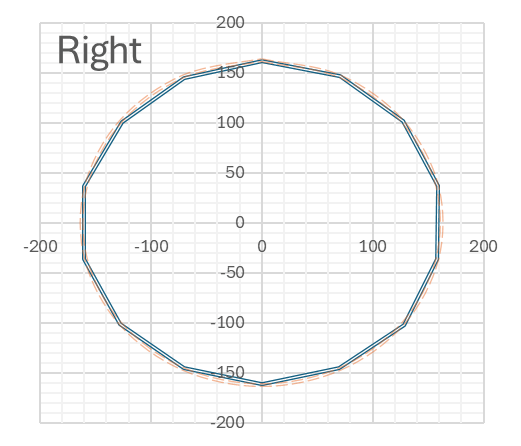

However, this shift introduces challenges in testing and optimisation. True aerodynamic efficiency often requires tyres that maintain a consistent profile without excessive ballooning. The growing variety of tyre and wheel combinations makes the use of a single control tyre increasingly impractical for testing purposes. Despite these complexities, basic aerodynamic sweeps and data visualisation (DNV) techniques remain valuable for assessing and comparing performance. Nevertheless a basic sweep and DNV (Wikipedia as DMV for Dimitriev) was carried out.

The results were as expected: the shallow rim depth results in a very stable wheel, albeit at the expense of ultimate straight-line drag.

On the Road

The wheels feel like any other 35mm wheel in riding. They did not detention by a discernable amount when they were pumped up. Crosswind stability was very good, given that it’s a shallow wheelset this was predicted. The use of carbon spokes does lead to a slight increase in the transmission of road vibration.

The ultimate straight line aerodynamic performance is impacted by the shallow depth. In situations where the bike has to be accelerated from a standing start, the lightweight nature of the wheels do mean it accelerates faster than much deeper wheels.

Overall

These are without doubt a competent set of wheels. They do not have the brand appeal yet but as a combination of quality components together in a well built package, there is not much to go wrong. The wheels have been used on the road and in gravel scenarios. They functioned perfectly in both applications.

Watch on YouTube

Links

Discount code

You can use the discount code hambini or HAMBINIENGINEER to get 5% off. A link to up to date discount codes is here