B542 Headset Bearing 33.34×44.45×7.14 0/0 3D3 B542

£8.95 Ex. VAT

B542 Headset Bearing 33.34×44.45×7.14 0/0 3D3 B542 This is a chrome steel Angular Contact Headset Bearing designed for use in Bicycle steering systems. Photographs are for illustration purposes

42 in stock

Description

This is a premium HPE (Hambini Performance Engineering) headset bearing designed for Front Fork steerer systems on bicycles. This is a chrome steel bearing with hardened inner and outer raceways. The internal cage that supports and spaces the balls is reinforced to improve axial stiffness. The geometrical and dimensional tolerances and running clearances would be broadly in line with JIS B1514 Tolerance Class 0 (There is no ISO standard for Bicycle Headset Bearings).

This bearing has been made to Hambini specifications and manufacturing procedures. The types of seals, the grease, the contact angles and the materials have been specified to ensure optimum performance and continued reliability. The bearings are made in a ISO 9002 certified factory.

- Internal Diameter(mm): 33.34

- External Diameter(mm): 44.45

- Depth(mm): 7.14

- Internal Chamfer(degrees): 0

- External Chamfer(degrees): 0

- Material: AISI 52100 DIN 1.3505 SUJ2 EN31

- Seals: Double Rubber

- Seal Material: Nitrile (NBR)

- Grease: Shell Gadus / Mobil XHP / Petronas EP2

- Grease Rating: NLGI 2

- Alternative Part Numbers:

Notes:

- Made to Hambini Specifications

- The majority of HPE headset bearings are made in Taiwan

- 1 Year Warranty (this does not cover wear)

- In the event of a HPE bearing being unavailable, you will be supplied with a bearing from the German company ZEN

The Hambini Difference

HPE bearings are finished in a 3 step process that involves multiple grinding stages followed by 2 – stage superfinishing of the raceways. This is accomplished with the use of Saint-Gobain Norton abrasives in an ISO registered factory. Superfinishing results in smoother running surfaces and smoother bearing rotation. Whilst vibration levels for headset bearings are largely irrelevant, vibration does correlate directly with the quality of the bearing. HPE bearings typically exhibit 30-40% lower vibration than competitor products.

The grease in HPE bearings is a heavy duty NLGI 2 grease. Headset bearings will never complete one rotation in their lifetime and generate little to no heat. The bearings have a 90% grease fill rate and has water repelling properties. A thick, pure marine grade of grease has not been used owing to the widely documented propensity for thick grease to develop cavities and thus provide no protection. This is exacerbated by the lack of bearing rotation meaning their is little opportunity for heat generation to turn the grease from semi solid material to fluid.

Each Bearing has been designed from the ground up, they are not derivatives of 6000 and 7000 series bearings that have been modified to suit the boundary dimensions. The contact angles, ball sizes, cages and races have been designed for the load characteristics.

Bearing Quality

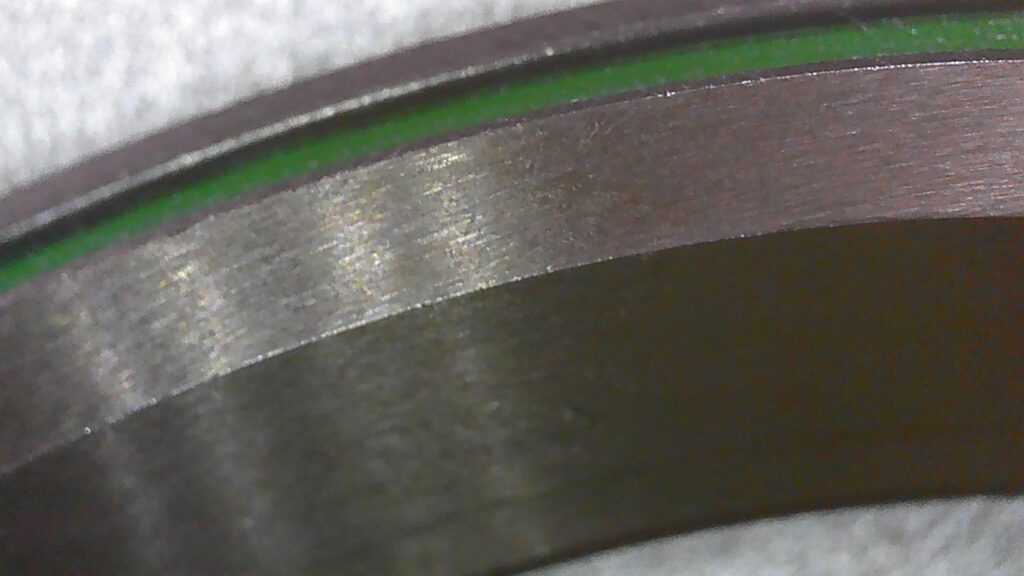

There is a considerable difference in the quality of headset bearings. Many bearings that are imported from the far east feature raceways that are neither hardened nor ground. Notice the picture below showing pinch marks where the material has chipped away (coloured orange) and poor finishing (circumferential groove).

The pictures below show Hambini Headset bearings as a comparison.

Need some Help?

Additional information

| Inside Diameter (ID) | 33.34 |

|---|---|

| Outside Diameter (OD) | 44.45 |

| Bearing Thickness/Height | 7.14 |

| Chamfer Angle (Internal) | 0 |

| Chamfer Angle (External) | 0 |

Reviews

There are no reviews yet