Hambini Racing BB30 Bottom Bracket Shimano Crankset (Silver)

£197.00 Ex. VAT

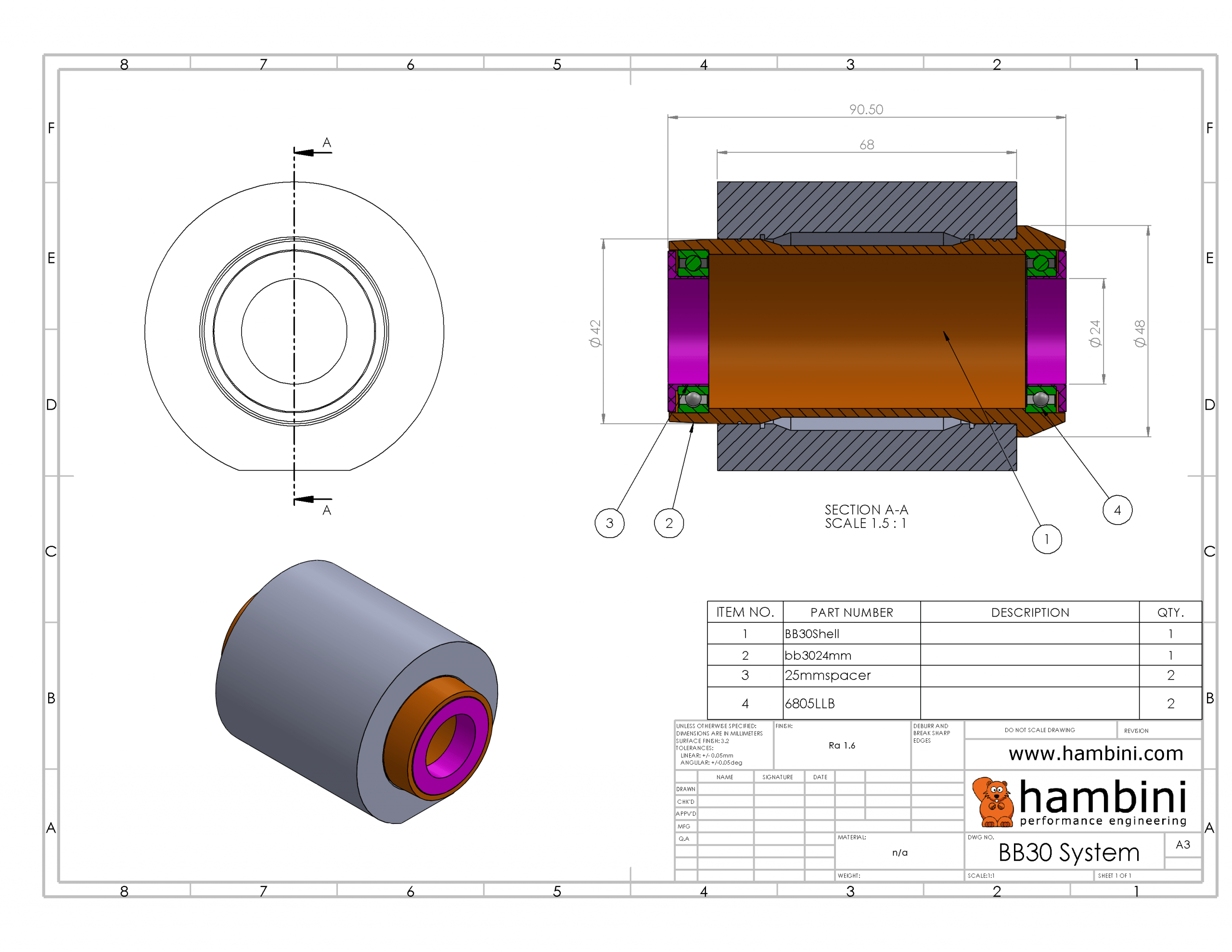

This bottom bracket is designed to interface a Shimano 24mm Hollowtech 2 Crankset (Sora, Tiagra, 105, Ultegra, Dura Ace) and Shimano Compatible (Some ROTOR and FSA) 24mm Cranksets with a bike frame that uses a BB30 Bottom Bracket (42mm Nominal Inside Diameter x 68mm wide).

Out of stock

Description

This bottom bracket is designed to interface a Shimano 24mm Hollowtech 2 Crankset (Sora, Tiagra, 105, Ultegra, Dura Ace) and Shimano Compatible (Some ROTOR and FSA) 24mm Cranksets with a bike frame that uses a BB30 Bottom Bracket (42mm Nominal Inside Diameter x 68mm wide).

Hambini Racing Bottom Bracket Overview

- 20% stiffer than Hambini Standard Bottom Brackets

- As used in the Pro-Peloton

- One Piece design aligns the bearings perfectly, reducing the likelihood of creak

- NTN Bearings Ultra Low Friction Bearings fitted as standard in Road applications. Fully Sealed NTN/FAG Bearings fitted in MTB Applications

- No Hammers are required to install or Remove the Bottom Bracket

- Fully Serviceable, the bearings can be replaced quickly and easily

- It is supplied with fitting adaptors in M12 (or 1/2 inch), a press or studbar will be required to facilitate installation

- One year warranty on the bottom bracket body

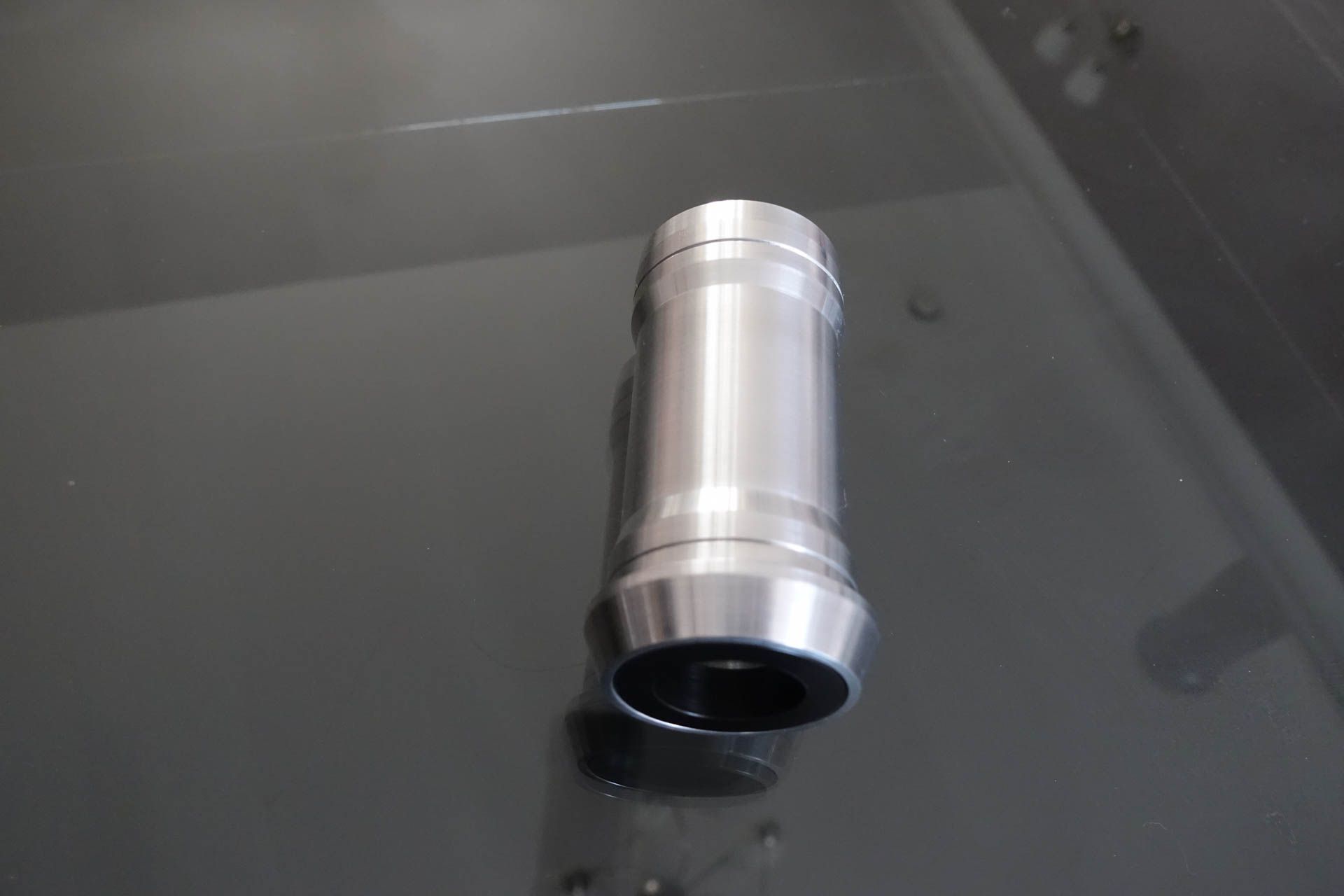

Precision Engineered and Manufactured in the United Kingdom

Hambini Bottom Brackets are amongst the lowest friction bottom brackets in the world. They are used by recreational cyclists, road racers, triathletes and time trialists from around the globe. They are of proven design and are manufactured in the United Kingdom. These units are of a one piece construction which makes them inherently resistant to creak, they will maintain perfect bearing alignment and function under loads in excess of 4000W.

Hassle-Free Maintenance

All Hambini bottom brackets can be installed and removed with a conventional bearing press, they use a controlled method of installation using the recommended fitting adaptors, they require no hammers or specialized tooling for removal. Additionally, the wearing component – the bearings – can be serviced in situ or removed within just a few minutes. The bottom bracket has been designed to be fully rebuildable.

Unrivalled Performance

Unloaded bearing spin tests are a poor measure of frictional performance but they do highlight good bearing alignment. The link below is to a video of a Hambini Racing Bottom Bracket that had completed 10,000km

Class Leading Parasitic Drag Loss (Friction)

The graph below shows how Hambini bottom brackets perform in comparison to the bottom brackets of other manufacturers. The test conditions model real world cycling and more importantly mimics realistic frame tolerances. All of these tests have been conducted with an eccentricity of 0.1mm which is generally the maximum permitted in frame specifications – the reality is tolerances have been known to be much worse than this. Misalignment is more critical to friction than the type of bearing ball material, a slight misalignment can easily outweigh the difference between a top of the range NTN bearing and a mediocre ebay no name bearing. The results show that bottom brackets which have an element of structural linkage between the drive and non-drive sides (one piece/threaded etc) perform much better than those which are multi piece.

The high torque and low RPM of pedaling causes high Hertzian contact stresses on bearing surfaces which cause friction levels to change over time. Those bottom brackets which have used ceramic bearings, start off with fairly low levels of friction but over time their friction increases dramatically. The super hard ceramic balls grind a track into the comparatively soft bearing races causing friction to increase. This would be analogous to trying to drive a locomotive train on a road, the wheels would cut grooves into the road surface due to the huge difference in surface hardness.

Bottom Bracket Stiffness

A Hambini BB is a one piece bottom bracket. It actively contributes to the stiffness of the bike’s pedaling platform. Threaded and multi piece bottom brackets have an element of play in their design so they do not contribute anywhere near a comparative level of stiffness. Reviewers of Hambini BB’s often comment on their feeling of improved stiffness, this is due to them being one piece and undergoing a proprietary heat treatment process. This makes them stronger and stiffer. This is a difference the end user cannot see – but they can feel.

Support

A lot of support questions can be answered by visiting the support section.

Popular support topics:

- Installation of a Pressfit Hambini Bottom Bracket

- Servicing of a Hambini Bottom Bracket (Bearing Service)

- Removal of a Hambini Bottom Bracket

Still need some help?

You can contact support on support@hambini.com or use the Contact Form

BB30 Bearing Kit 6806-2RS 61806-2RS NTN NSK NKE SKF FAG Koyo

BB30 Bearing Kit 6806-2RS 61806-2RS NTN NSK NKE SKF FAG Koyo  Hambini BB Removal Tool (BB86 Close fitting)

Hambini BB Removal Tool (BB86 Close fitting)

Bryn Williams –

BB required as I changed my spesh cranks to Shimano DA’s. This bottom bracket did the job. Very well made.

Jemma Stevens –

I can’t thank Hambini enough. The quality of service and support throughout the buying and fitting process has been first class. I had my bike shop install this and they ran into a few problems with my bike frame. All problems were sorted out within the day, I’m really glad I ditched the Cannondale cranks and went to Shimano. The shifting is so smooth and there is not even a hint of any noise from the bottom bracket. I would recommend it.

R Blair –

Fitted in my TM01 to use a Shimano crank. Went in easily and have had zero problems with it after several 100 mile rides. I have seen lots of bottom brackets over the years. This is extremely well made and like a piece of art. The bit you don’t see, is the service you get from Hambini. It is LEAGUES ahead of any other bike manufacturer I have dealt with. Refreshing and prompt. If you think you are dealing with a nutcase like he comes across on his YT channel, think again. His engineering is right up there.

David Frei –

Loctite 641 is not available at all in hun and very hard to fund a good retailer. Please advice alternatives for install or be a loctite retailer in this case. I have to wait now 2 more weeks to start installation 🙁 otherwise I will be glad with everything … I hope.

Mark D. –

Installation was easy, though did require a little more force than I was expecting getting it all the way into the BB, but not too much bother. It looks like a work of art, blends seamlessly with the aluminum shell of the BB30 on my Felt B14. Zero gaps between the BB and the shell, checked with a 0.038mm feeler gage. This is the smoothest I’ve ever felt my drive train and I was replacing another bb30 to shimano conversion from a fairly popular manufacturer using ceramic bearings. Its a little pricy but so far I definitely think it’s worth it!

Rodney R. –

Haven’t had time to install.

lucaslonghurst –

5-star service from start to finish. The quality of the product speaks for itself and will surely last for years and years to come. Yes, it’s expensive but it’s worth it to save the headache and shop time when other, inferior, options begin to inevitably creak. Plus, the bearings are as smooth as butter and the entire piece is incredibly stiff. Planning on ordering a second one for my other bike as well. Just order – you won’t regret it.