MH-P03K Headset Bearing 30.15x41x6.5 36/45 2C2 K336H6.5 MR122 TH873E MR054 HSS20130K PT-R401

£8.95 Ex. VAT

MH-P03K Headset Bearing 30.15x41x6.5 36/45 2C2 K336H6.5 MR122 TH873E MR054 HSS 20130K PT-R401 This is a chrome steel Angular Contact Headset Bearing designed for use in Bicycle steering systems. Photographs are for illustration purposes

8 in stock

Description

This is a premium HPE (Hambini Performance Engineering) headset bearing designed for Front Fork steerer systems on bicycles. This is a chrome steel bearing with hardened inner and outer raceways. The internal cage that supports and spaces the balls is reinforced to improve axial stiffness. The geometrical and dimensional tolerances and running clearances would be broadly in line with JIS B1514 Tolerance Class 0 (There is no ISO standard for Bicycle Headset Bearings).

This bearing has been made to Hambini specifications and manufacturing procedures. The types of seals, the grease, the contact angles and the materials have been specified to ensure optimum performance and continued reliability. The bearings are made in a ISO 9002 certified factory.

- Internal Diameter(mm): 30.15

- External Diameter(mm): 41

- Depth(mm): 6.5

- Internal Chamfer(degrees): 36

- External Chamfer(degrees): 45

- Material: AISI 52100 DIN 1.3505 SUJ2 EN31

- Seals: Double Rubber

- Seal Material: Nitrile (NBR)

- Grease: Shell Gadus / Mobil XHP / Petronas EP2

- Grease Rating: NLGI 2

- Alternative Part Numbers: MH-P03K, K336H6.5, MR122, TH873E, MR054, MR115, HSS 20130K, PT-R401

- The most popular 1-1/8″ bearing -cane creek fit

Notes:

- Made to Hambini Specifications

- The majority of HPE headset bearings are made in Taiwan

- 1 Year Warranty (this does not cover wear)

- In the event of a HPE bearing being unavailable, you will be supplied with a bearing from the German company ZEN

The Hambini Difference

HPE bearings are finished in a 3 step process that involves multiple grinding stages followed by 2 – stage superfinishing of the raceways. This is accomplished with the use of Saint-Gobain Norton abrasives in an ISO registered factory. Superfinishing results in smoother running surfaces and smoother bearing rotation. Whilst vibration levels for headset bearings are largely irrelevant, vibration does correlate directly with the quality of the bearing. HPE bearings typically exhibit 30-40% lower vibration than competitor products.

The grease in HPE bearings is a heavy duty NLGI 2 grease. Headset bearings will never complete one rotation in their lifetime and generate little to no heat. The bearings have a 90% grease fill rate and has water repelling properties. A thick, pure marine grade of grease has not been used owing to the widely documented propensity for thick grease to develop cavities and thus provide no protection. This is exacerbated by the lack of bearing rotation meaning their is little opportunity for heat generation to turn the grease from semi solid material to fluid.

Each Bearing has been designed from the ground up, they are not derivatives of 6000 and 7000 series bearings that have been modified to suit the boundary dimensions. The contact angles, ball sizes, cages and races have been designed for the load characteristics.

Bearing Quality

There is a considerable difference in the quality of headset bearings. Many bearings that are imported from the far east feature raceways that are neither hardened nor ground. Notice the picture below showing pinch marks where the material has chipped away (coloured orange) and poor finishing (circumferential groove).

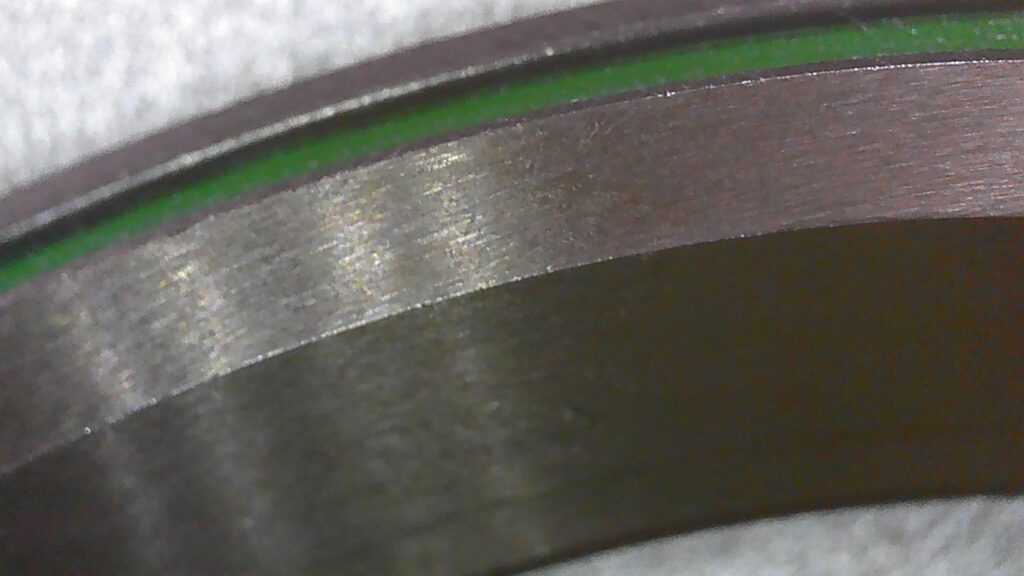

The pictures below show Hambini Headset bearings as a comparison.

Need some Help?

Additional information

| Inside Diameter (ID) | 30.15 |

|---|---|

| Outside Diameter (OD) | 41 |

| Bearing Thickness/Height | 6.5 |

| Chamfer Angle (Internal) | 36 |

| Chamfer Angle (External) | 45 |

NTN 6901 LLU 12x24x6 Fully Contacting Seal

NTN 6901 LLU 12x24x6 Fully Contacting Seal

Anthony P –

This bearing replaced a unit that lasted only a month from Aire bearings. The fit on this is much better and it doesn’t feel clunky. Competitively priced and I would not hesitate in buying from Hambini again.

Hassan –

The quality of this bearing and some of the others that are similarly priced is like day and night. Good fit, very smooth. The bearing raceways do not rock.

Time will tell as to the seal quality. On visual inspection, they do look to be well sealed.

paul alexander –

Ordering was simple as all key dimensions were stated clearly. Communication was eccelent and shipping fast. Bearing were great quality.

Darren T. –

It’s a bearing, but it’s a good bearing and price/delivery was great!

gary s. –

Another Quality product from Hambini

David G. –

Mark E. –

D T. –

As always, Hambini bearings are great, the web site is easy to navigate and delivery is fast

Mike F. –

excellent bearings at a great price

Milosz Pogoda –

Anonymous –

A superb bearing.

admin –

I did try to reach out to this customer to offer a refund/replacement and also to retrieve the bearing to find out if it was defective. I didn’t get a response. I do take comments like this quite seriously, so I checked the remaining 36 bearings in stock (at the time). All of them were found to be within tolerance.

admin –

Update: I retrieved the bearing from the customer. Inspection showed the bearing had not been supplied by me. The colour of the seals, the colour of the inner and outer races were all different.

I have left the original review and rating up for transparency. Thanks Hambini

Michael Case –

Headset bearings, fitted nicely, delivered quickly, feel silky smooth.

Jeff B. –

I trust Hambini 100%. I was able to find the right size headset bearings on the Hambini site. He even teaches you how to size them in case you’re not sure.

JEFFREY –

Really very nice bearing set. Built three bikes this year…wish I knew Hambini had headset bearings earlier. Even shipping was quick from UK to USA.

Findlay –

1 of 2 quality bearings purchased for an excellent price and delivered within a few days. Fantastic service!