Bicycle Headset Bearings: A Practical Guide

Introduction

Headset bearings form an integral part of a bicycle’s steering system. They are usually found in pairs. A single bearing at the top of the head tube and another bearing at the lower end of the head tube. Headset bearings operate at very low speed and their primary function is to support axial load (ie the weight of the bike and rider) as opposed to radial load which is the turning of the handlebars.

They are commonly angular contact bearings with some chamfers used for locating geometric positions. Occasionally, some large deep groove ball bearings are used.

This guide will explain how to measure them and provides a table of common sizes.

Purchasing

You can purchase replacement headset bearings from the Hambini Headset Bearing Shop.

Replacement

Headset bearings are in a very exposed position, which makes them vulnerable to contamination from road grime and sweat.

It is highly recommended that headset bearings are replaced as a pair – ie the upper and lower bearings are both replaced at the same time. The bearings are designed with the ability to cope with mild misalignment, and this causes running tracks to form inside the raceways. Replacing a single bearing will often result in the premature failure of the second unchanged bearing.

It should be noted that headset bearings are angular contact bearings and thus require ample preload (in the right direction). Quite often they will feel slightly notchy when insufficient preload is applied (this is more prevalent in bearings with an axial seal such MH-P08xx series units). This leads to many bearings being replaced before they are actually worn. Caution should be exercised when conducting “spin tests” in fingers. This applies equally to used bearings and new bearings.

Measuring

Headset bearings are notoriously problematic because they do not follow conventional ISO or JIS standards for numbering. It is always advisable to measure the physical bearing if at all possible. Use of the bearing number to size the bearing is an option, but it is not recommended.

Headset bearings are often imperial derived (inch) sizes. The use of a vernier caliper or digital caliper is highly recommended. A micrometer would be advantageous.

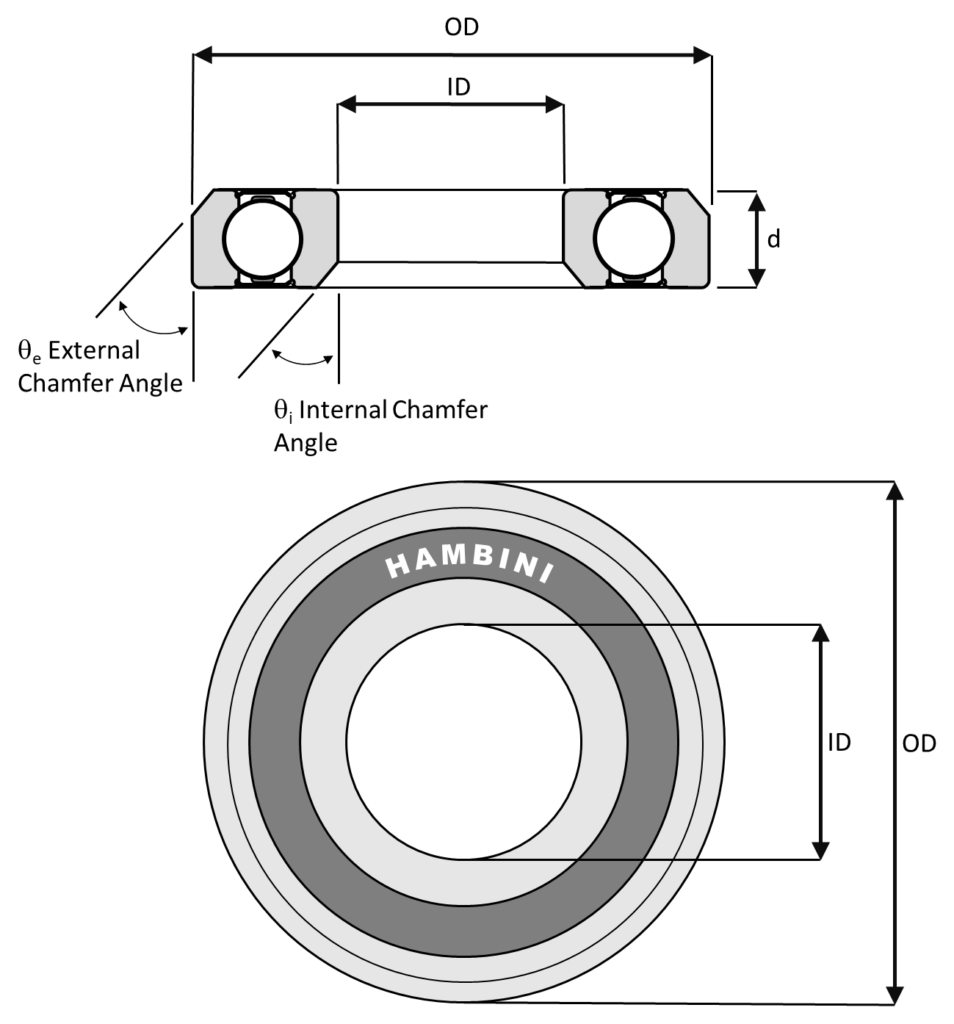

The figure below shows all of the measurements required to correctly identify a headset bearing.

- Inner Diameter (this does not need to be extremely accurate)

- Outer Diameter

- Height (width)

- Internal (Inner) Chamfer Angle in degrees

- External (Outer) Chamfer Angle in degrees

Outside Diameter

Measurement of the outside diameter of the bearing is straightforward; position the jaws on the outside of the bearing and note the measurement.

Inside Diameter

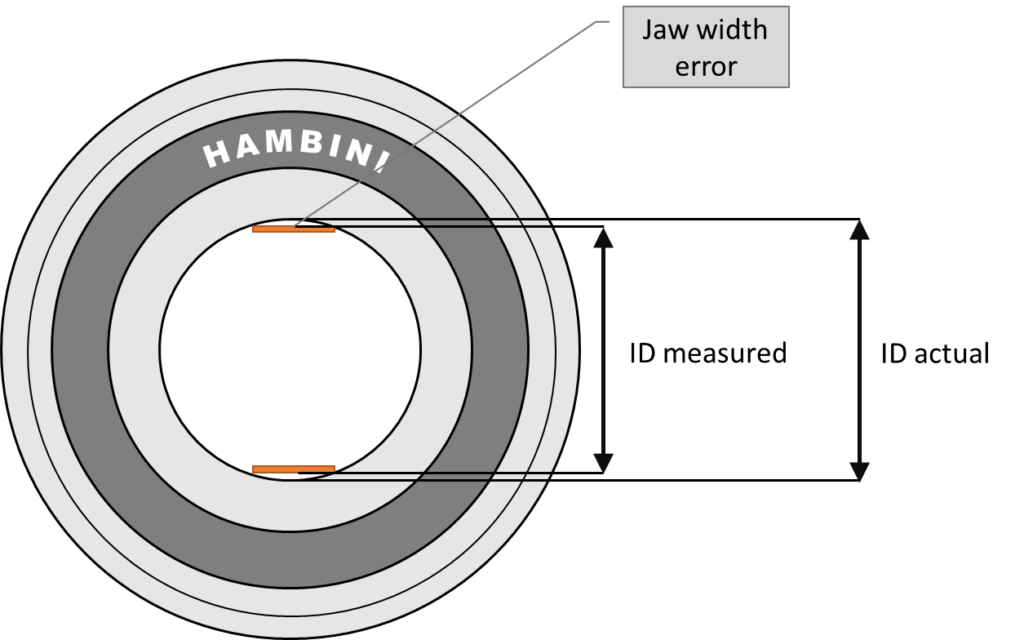

Measurement of the internal diameter (the bore) is prone to parallax and jaw width errors, Vernier jaws are not infinitesimally thin, and the resulting jaw width on small bearings can cause the measured ID to be smaller than the actual ID. Measuring the external diameter of the corresponding part is often preferable – usually the diameter of the crown race.

IMPORTANT: Measurement Accuracy

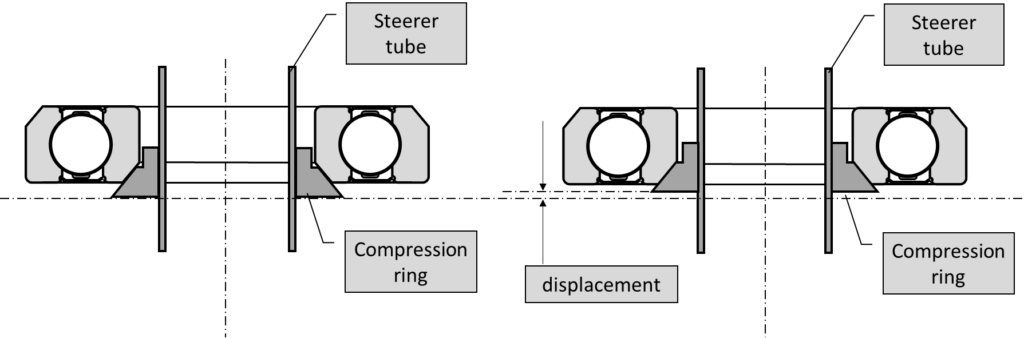

The critical dimensions of a headset bearing are the outer diameter and the height. The inner diameter is not as critical and can vary by up to 0.3mm between manufacturers. The inner diameter does not touch the steerer tube. It is held off it by a corresponding chamfered wedge crown or compression ring.

The physical effect of a slight size mismatch is to move the bearing (or the compression ring – depending on the datum) slightly up or down. The diagram below shows this is in practice. The setup on the right has a slightly tighter compression ring, which forces the compression ring upwards. This diagram is greatly exaggerated and a typical mismatch of 30.15mm vs 30.5mm would produce approximately 0.2mm of vertical movement, which is well within typical frame manufacturing tolerances.

Chamfer Angles

Headset bearings are often chamfered on the inner and outer races. the chamfers are generally for locating purposes and to improve the compressive stiffness of the steering assembly. Chamfer angles are commonly

- Unchamfered 0deg

- 36 deg (bearings with a 36 degree inner chamfer angle are often (but not always) coloured black on the inner race)

- 45 deg (most popular)

Chamfer angles may not always be the same on the inner and outer races. Combinations of 36 degrees and 45 degrees on the same bearing are rare but do exist.

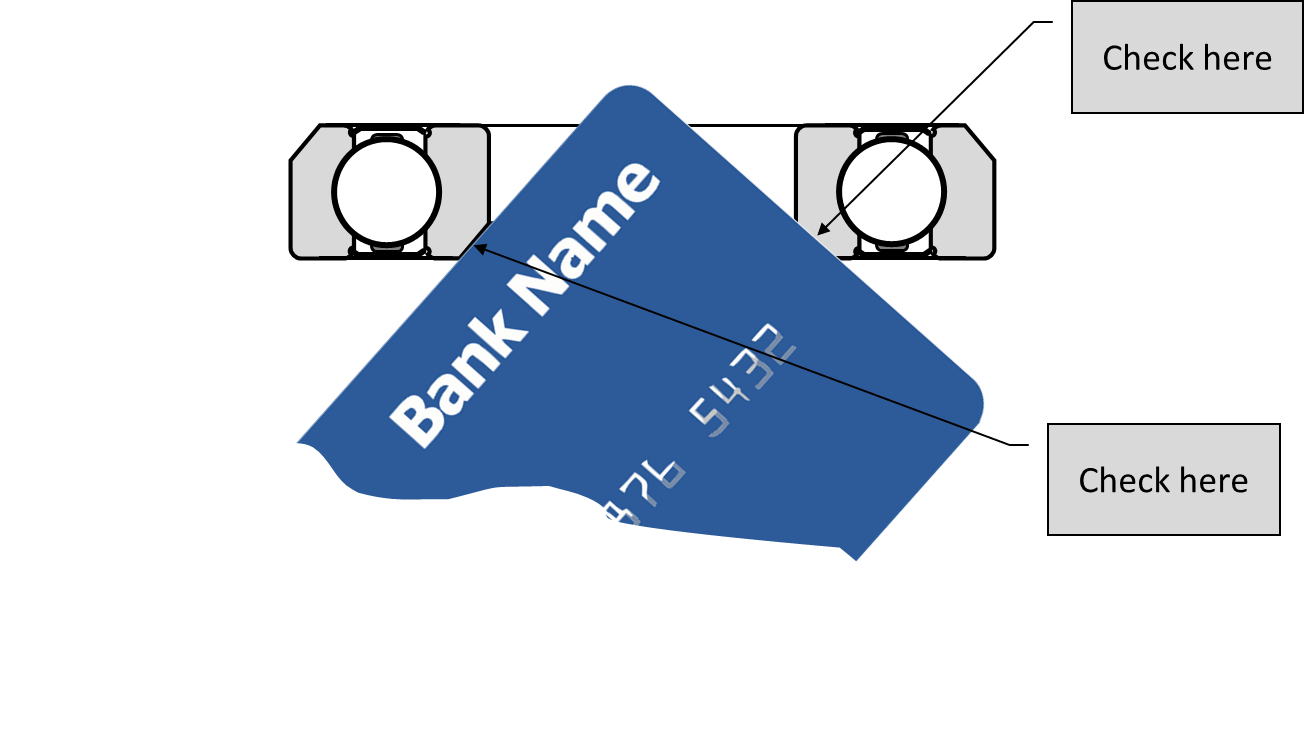

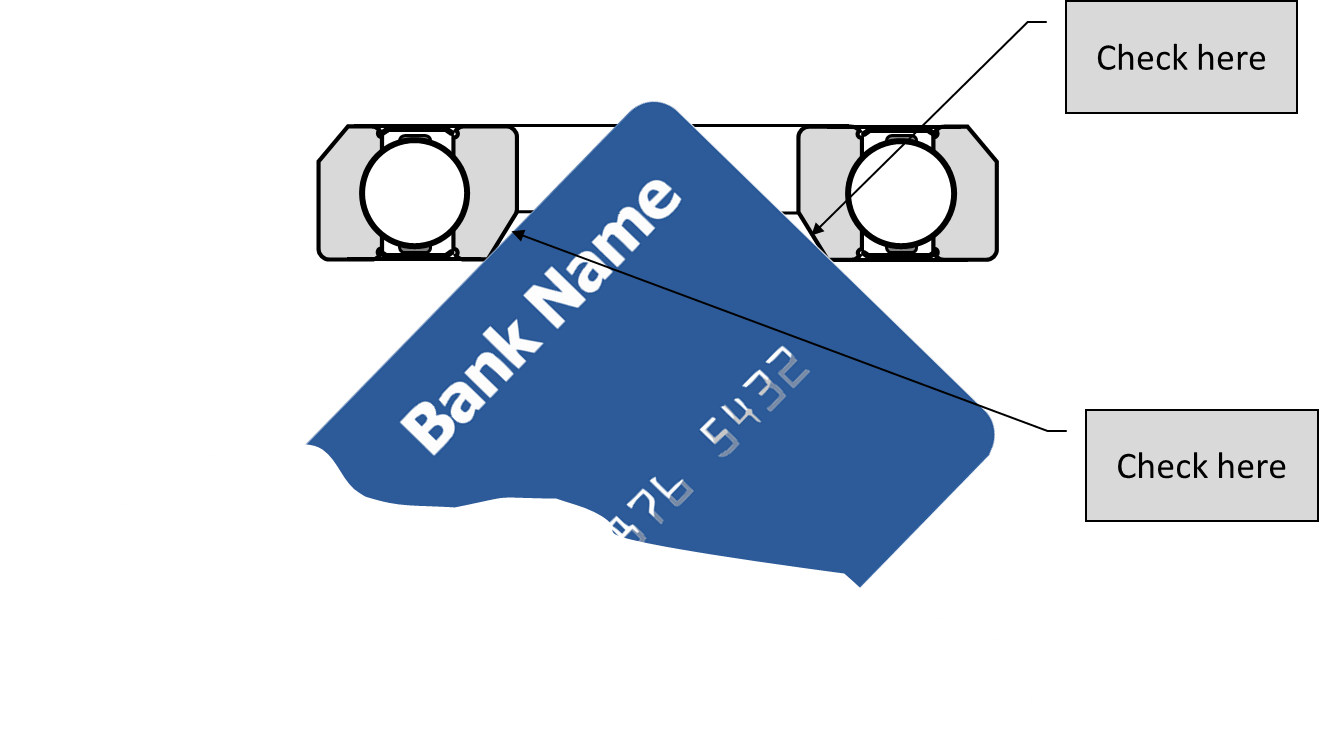

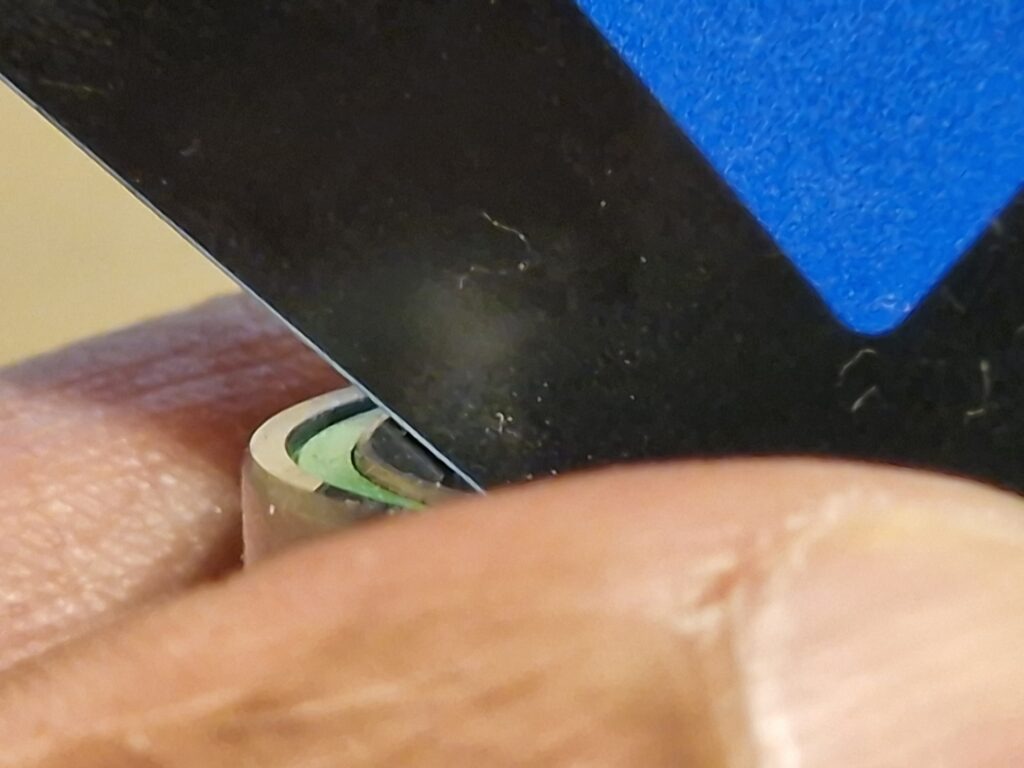

Testing for 45 degree chamfer angles is straightforward, an object such as a credit card is ideal. Insert the credit card into the bore and ensure that both edges touch fully on the internal chamfer. If it does not touch fully and contact is only made on a section of the chamfer (usually the widest point), it will likely be 36 degrees.

The photos below show the method practically on a bearing with a 45 degree chamfer on the inner ring..

Bearing Quality

There is a considerable difference in the quality of headset bearings. Many bearings that are imported from the far east feature raceways that are neither hardened nor ground. Notice the picture below showing pinch marks where the material has chipped away (coloured orange) and poor finishing (circumferential groove).

The pictures below show Hambini Headset bearings as a comparison.

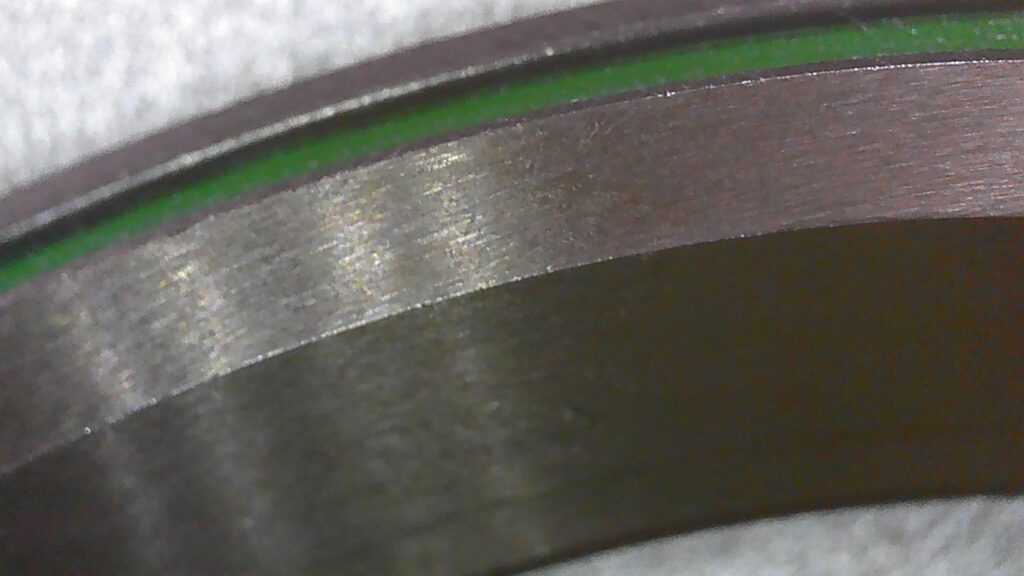

Bearing Discoloration and Machining

Most headset bearings are produced using a process similar to that of deep groove ball bearings, where the materials are first hardened and then ground to their final dimensions. However, certain headset bearing sizes feature geometries that are difficult to achieve through grinding alone. In these cases, machining is used instead, which can result in surfaces that are comparatively rougher than those with a ground finish. Discoloration is often found on these bearings. While this typically does not impact the bearing’s performance, the appearance may be less visually refined.

Some common examples are MH-PO8H8F (which has a lip on the inside), MH-P25K and MH-P16.

Common Headset Bearing Size Table

The table below details a comprehensive list of headset bearing sizes. They are arranged in ascending order of Internal Diameter (ID).

| Item No. | Inside Diameter (mm) | Outside Diameter (mm) | Depth (mm) | Internal Chamfer Angle | External Chamfer Angle | Alternative Part Num.1 | Alternative Part Num.2 | Alternative Part Num.3 | Alternative Part Num.4 | Alternative Part Num.5 | Alternative Part Num.6 | Alternative Part Num.7 |

| K936H6.5 | 27.15 | 38 | 6.5 | 36 | 45 | MH-P09K | ||||||

| K945H6.3 | 27.15 | 38 | 6.3 | 45 | 45 | MH-P09H6.3 | ||||||

| K3039H6.5 | 30.15 | 39 | 6.5 | 45 | 45 | MH-P04 | ||||||

| K336H6.5 | 30.15 | 41 | 6.5 | 36 | 45 | MH-P03K | MR122 | TH873E | MR054 | MR115 | HSS 20130K | PT-R401 |

| K336KH6.5 | 30.15 | 41 | 6.5 | 36 | 36 | |||||||

| K345H6.5 | 30.15 | 41 | 6.5 | 45 | 45 | MH-P03 | ||||||

| K345H7 | 30.15 | 41 | 7 | 45 | 45 | MH-P03H7 | TK410 | |||||

| K345H7.7 | 30.15 | 41 | 7.7 | 45 | 45 | MH-P03H7.7 | ||||||

| K845H6.5 | 30.15 | 41.8 | 6.5 | 45 | 45 | MH-P08 | ||||||

| K845H7 | 30.15 | 41.8 | 7 | 45 | 45 | MH-P08H7 | ||||||

| K845H7.7 | 30.5 | 41.8 | 7.7 | 45 | 45 | MH-P08H7.7 | ||||||

| K845H8 | 30.5 | 41.8 | 8 | 45 | 45 | MH-P08H8 | ||||||

| K845H8F | 30.5 | 41.8 | 8 | 45 | 45 | MH-P08H8F | TH870E(FSA) | MR121 | ACB845F | ACB418F | ||

| K32438H7 | 32.4 | 43.8 | 7 | 45 | 45 | |||||||

| K418H6 | 32.7 | 41.8 | 6 | 45 | 45 | MR136 | ||||||

| K3344H6 | 33 | 44 | 6 | 36 | 45 | |||||||

| B542 | 33.34 | 44.45 | 7.14 | 0 | 0 | |||||||

| K34468H7 | 34 | 46.8 | 7 | 45 | 45 | MH-P17 | MR082 | TH-970 | 160-6738 | |||

| K34469H7 | 34.1 | 46.9 | 7 | 45 | 45 | MH-P22 | ||||||

| K3544H5.5 | 35 | 44 | 5.5 | 36 | 45 | |||||||

| K3547H7 | 35 | 47 | 7 | 36 | 45 | |||||||

| K3547H8 | 35 | 47 | 8 | 45 | 45 | |||||||

| K37469H7 | 37 | 46.9 | 7 | 45 | 45 | MR137 | ||||||

| K3748H7 | 37 | 48 | 7 | 45 | 45 | |||||||

| K3749H7 | 37 | 49 | 7 | 45 | 45 | MH-P21 | ||||||

| B543 | 37.9 | 50.8 | 7.14 | 0 | 0 | |||||||

| K4051H7 | 40 | 51 | 7 | 45 | 45 | |||||||

| K4052H12 | 40 | 52 | 12 | 45 | 45 | T808 | ||||||

| K4052H6.5 | 40 | 52 | 6.5 | 45 | 45 | |||||||

| K4052H7 | 40 | 52 | 7 | 45 | 45 | MH-P16 | MR128 | TH-070E | MR170 | |||

| K4052H8 | 40 | 52 | 8 | 45 | 45 | MH-P16H8 | ||||||

| K4052KH6.5 | 40 | 52 | 6.5 | 36 | 45 | MH-P25K | BAA0006K | ACB 6808 CC | ||||

| K515H7 | 40 | 51.5 | 7 | 45 | 45 | |||||||

| K518H8 | 40 | 51.8 | 8 | 45 | 45 | |||||||

| K518KH8 | 40 | 51.8 | 8 | 36 | 45 | MH-P28K | MR127 | MR110 | TH-073 | ACB518K | ||

| K519H8 | 40 | 51.9 | 8 | 45 | 45 |